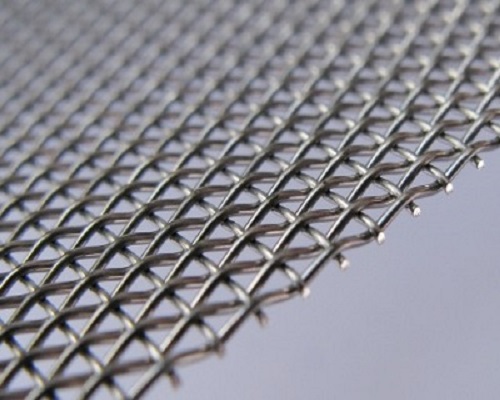

2507 Super Duplex Stainless Steel Mesh

Key Features:

- Great resistance to general corrosion

- Excellently high mechanical strength and functional stability

- Mesh Size: 0.2mesh/inch to 300mesh/inch

- Wire Dia: 0.03mm to 8.0mm

Product Description:

2507 super duplex stainless steel mesh (UNS S32750) is a high-strength, ultra-corrosion-resistant wire mesh designed for the most demanding environments, including offshore, chemical processing, and desalination. It offers superior performance over standard duplex 2205 and austenitic steels (316L).

🔹 Key Properties of 2507 Super Duplex Stainless Steel Mesh:

| Property | Value | Advantage Over 316L/Duplex 2205 |

| Composition | 25% Cr, 7% Ni, 4% Mo, 0.3% N | Higher pitting/crevice resistance |

| Tensile Strength | 800-1000 MPa | 2x stronger than 316L |

| Yield Strength | 550-600 MPa | 3x higher than 316L |

| Pitting Resistance (PREN) | ≥42 | Better than 2205 (PREN ~35) |

| Corrosion Resistance | Excellent in chlorides, acids, H₂S | Outperforms 316L in sour gas/seawater |

| Max Temperature | Up to 300°C (572°F) | Similar to 2205, but stronger |

🔹 Weave Types & Specifications:

- Plain Weave (Most Common)

– Balanced grid for filtration, sieving, and structural use.

– Mesh Sizes: 1 to 200 mesh.

– Wire Diameters: 0.05mm to 5mm.

- Twilled Weave

– Stronger, denser for high-pressure filtration (oil/gas, chemical).

- Dutch Weave (Micron Filtration)

– Ultra-fine for desalination, fuel, and chemical filtration.

- Welded Mesh (Structural Applications)

– Used in offshore platforms, architectural facades, and security screens.

🔹 Top Applications of 2507 Super Duplex Mesh:

✅ Oil & Gas (Extreme Environments)

– Subsea pipelines, well screens, sour gas (H₂S) filtration – resists sulfide stress cracking.

✅ Desalination & Marine

– Seawater reverse osmosis (RO) filters, shipbuilding – superior chloride resistance.

✅ Chemical & Petrochemical

– HCl, sulfuric acid filtration, reactor screens – handles aggressive chemicals.

✅ Power & Nuclear

– Cooling systems, flue gas scrubbers – withstands high temps + corrosion.

✅ Architectural & Security

– Blast-resistant panels, coastal facades – high strength + aesthetics.

🔹 Comparison: 2507 vs. 2205 vs. 316L:

| Feature | 2507 (Super Duplex) | 2205 (Duplex) | 316L (Austenitic) |

| Strength | ⭐⭐⭐⭐⭐ (Highest) | ⭐⭐⭐⭐ | ⭐⭐ |

| Chloride Resistance | ⭐⭐⭐⭐⭐ (Best) | ⭐⭐⭐⭐ | ⭐⭐ |

| Cost | $$$$ | $$$ | $ |

| Weldability | Good (needs expertise) | Good | Excellent |

✔ Choose 2507 when:

– Extreme chloride/sour gas exposure (e.g., offshore, desalination).

– Higher strength is needed (e.g., structural mesh in corrosive environments).

🔹 Limitations of 2507 Super Duplex Mesh:

❌ Expensive (~2x the cost of 2205, ~4x 316L).

❌ Requires skilled welding (improper heat treatment can reduce corrosion resistance).

❌ Not for temps >300°C (risk of embrittlement).

+1 206 890 7337

+1 206 890 7337 sales1@nickel-wiremesh.com

sales1@nickel-wiremesh.com