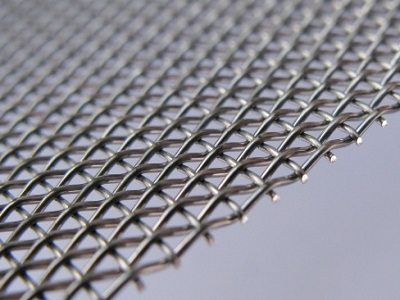

330 Stainless Steel Mesh

Key Features:

- Good resistance to oxidation and sulfur-bearing gases

- Less corrosion-resistant than 316L or 904L in acidic/chloride environments (not its primary use)

- Not ideal for wet/corrosive environments (use 316L or 904L instead)

- Weave Types: Plain weave, twill weave, or welded mesh

- Wide range of available specifications

Product Description:

330 Stainless Steel Mesh is a woven or welded mesh made from Alloy 330, a high-temperature austenitic stainless steel known for its excellent oxidation resistance and thermal stability. It’s commonly used in applications involving extreme heat, such as furnace components, heat treatment equipment, and industrial heating systems.

Key Features of 330 Stainless Steel Mesh:

- Material Composition (UNS N08330 / Alloy 330):

– Nickel (34-37%): Provides high-temperature strength and resistance to carburization.

– Chromium (17-20%): Enhances oxidation resistance.

– Iron (Balance): Maintains structural integrity under thermal cycling.

– Silicon (1-2%): Improves scale resistance in oxidizing environments.

– Low Carbon (≤0.08%): Reduces carbide precipitation, improving weldability.

- Temperature Resistance:

– Continuous Use: Up to 1150°C (2100°F).

– Intermittent Use: Up to 1200°C (2200°F).

– Resists oxidation, carburization, and nitriding in furnace atmospheres.

- Corrosion Resistance:

– Good resistance to oxidation and sulfur-bearing gases.

– Less corrosion-resistant than 316L or 904L in acidic/chloride environments (not its primary use).

– Weave Types: Plain weave, twill weave, or welded mesh.

– Mesh Sizes: Ranges from fine (e.g., 200 mesh for filtration) to coarse (e.g., 2 mesh for heat shielding).

– Wire Diameter: Varies based on application (thicker wires for high-stress heat zones).

Applications of 330 Stainless Steel Mesh:

- Heat Treatment & Furnace Components:

– Mesh belts for annealing, brazing, or sintering furnaces.

– Radiant tubes, muffles, and heat shields.

- Industrial Heating:

– Burner screens, combustion chambers, and exhaust systems.

- Aerospace & Gas Turbines:

– Heat exchanger screens and flame arrestors.

- Chemical Processing:

– High-temperature filtration in non-corrosive gases.

Advantages Over Other Stainless Steels (e.g., 304, 316L):

– Superior high-temperature performance (outlasts 304/316L above 900°C/1650°F).

– Resists thermal cycling fatigue (less warping/cracking).

– Excellent carburization resistance (critical in hydrocarbon-rich furnace atmospheres).

Limitations:

– Not ideal for wet/corrosive environments (use 316L or 904L instead).

– Higher cost due to nickel content compared to standard grades.

Equivalent Grades:

– UNS N08330 (ASTM/ASME)

– EN 1.4886 (European Standard)

– Common Trade Names: RA330®, Nicofe 330®.

When to Choose 330 Over Other Alloys?

– For extreme heat (e.g., furnaces, exhausts) where 304/316L would fail.

– When carburization resistance is needed (e.g., petrochemical processing).

– Avoid in chloride-rich or acidic environments (904L is better).

If you need this mesh, ensure it meets ASTM A240 (Alloy 330) for high-temperature reliability. Let me know if you’d like to know more details!

330 Stainless steel mesh chemical composition:

| C | Cr | Fe | Mn | Ni | P | Si | S | Cu | Pb | Sn |

| 0.08 % | 19 % | 40.2 % | 2 % | 36 % | 0.03 % | 0.75 – 1.50 % | 0.03 % | 1 % | 0.005 % | 0.025 % |

330 Stainless Steel Mesh Property data:

| Density | 0.289 lb per cubic inch |

| Specific Gravity | 7.99 |

| Specific Heat | 0.11 Btu/lb/ oF at (32 to 212 oF) |

| Magnetic Permeability | 1.02 |

| Modulus of Elasticity Tension | 28.5 |

| Melting point | 1400 oC to 1425 oC or 2550 oF to 2597 oF |

| Highest application temperature in air | 1035 oC to 1150 oC or 1895 oF to 2100 oF |

+1 206 890 7337

+1 206 890 7337 sales1@nickel-wiremesh.com

sales1@nickel-wiremesh.com