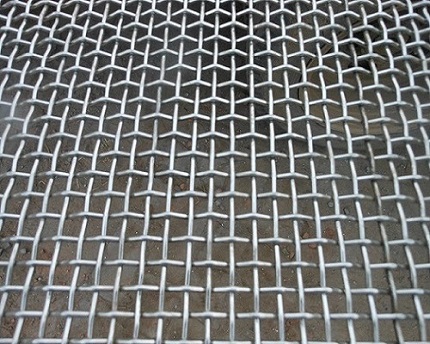

347 Stainless Steel Mesh

Key Features:

- Excellent resistance to intergranular corrosion (due to niobium stabilization).

- Good against oxidation, sulfur gases, and mild acids.

- Not ideal for chloride-rich environments (use 316L or 904L instead).

- Weave Types: Plain Weave, Twill Weave, Welded Mesh

- Mesh Sizes: From fine (200+ mesh) to coarse (1/4″ openings)

Product Description:

347 stainless steel mesh is made from niobium-stabilized austenitic 347 stainless steel, designed for high-temperature applications where welding or thermal cycling is required. It offers superior resistance to intergranular corrosion and performs exceptionally well in heat-intensive environments (e.g., furnaces, exhaust systems).

Key Features of 347 Stainless Steel Mesh:

Material Composition (UNS S34700 / AISI 347)

– Chromium (17-19%) → Provides oxidation & corrosion resistance.

– Nickel (9-13%) → Enhances toughness and high-temperature strength.

– Niobium (10× Carbon min.) ⭐ Key Advantage! → Prevents carbide precipitation (better than 321 in welding).

– Carbon (≤0.08%) → Low carbon reduces sensitization.

– Iron (Balance) → Maintains structural integrity.

Temperature Resistance:

– Continuous Service: Up to 900°C (1650°F).

– Intermittent Service: Up to 925°C (1700°F).

– Better than 304/316 in prolonged high-heat exposure.

Corrosion Resistance:

✔ Excellent resistance to intergranular corrosion (due to niobium stabilization).

✔ Good against oxidation, sulfur gases, and mild acids.

✔ Not ideal for chloride-rich environments (use 316L or 904L instead).

– Weave Types:

– Plain Weave (standard for filtration).

– Twill Weave (higher strength, smoother flow).

– Welded Mesh (rigid structural applications).

– Mesh Sizes: From fine (200+ mesh) to coarse (1/4″ openings).

– Wire Diameter: Varies by application (thicker for heat shielding).

Top Applications of 347 Stainless Steel Mesh:

Aerospace & Jet Engines

– Exhaust systems, afterburner components, heat shields.

Petrochemical & Refining

– Catalyst grids, furnace parts, cracking tubes.

Heat Treatment & Furnace Equipment

– Conveyor belts, radiant tubes, annealing trays.

Power Generation

– Boiler components, superheater screens.

Welded Fabrications

– Where post-weld corrosion resistance is critical.

Comparison with Similar Alloys:

| Property | 347 Mesh | 321 Mesh | 304 Mesh | 310 Mesh |

| Stabilizer | Niobium | Titanium | None | None |

| Max Temp | 900°C | 900°C | 870°C | 1150°C |

| Weldability | ⭐⭐⭐⭐ | ⭐⭐⭐ | ⭐⭐ | ⭐⭐ |

| Chloride Resistance | ⭐⭐ | ⭐⭐ | ⭐⭐ | ⭐ |

When to Choose 347 Mesh?

– High-temperature welded assemblies (better than 321).

– Applications requiring thermal cycling resistance.

– Where 304/316 would fail due to carbide precipitation.

When to Avoid 347?

– Marine/chloride exposure (use 316L or 904L).

– Extreme heat beyond 1000°C (use 310 or Inconel).

Fabrication Notes:

– Welding: Use 347 filler metal for best results.

– Work Hardening: Can be formed but may require annealing.

– Avoid Contamination: Keep away from carbon steel tools.

Standards & Equivalent Grades:

– UNS S34700 (ASTM/ASME)

– EN 1.4550 (European Standard)

– AISI 347 (Common U.S. designation)

Final Verdict

347 stainless steel mesh is ideal for high-temperature, welded applications where intergranular corrosion resistance is crucial. It outperforms 304/316 in heat and 321 in weld stability, making it a top choice for aerospace, petrochemical, and furnace components.

For higher temps (1100°C+), consider 310 or RA330. For marine/acidic environments, 316L or 904L is better.

+1 206 890 7337

+1 206 890 7337 sales1@nickel-wiremesh.com

sales1@nickel-wiremesh.com