Monel Mesh

Key Features:

- Superior Corrosion Resistance

- High Strength & Toughness

- Excellent Fabrication Properties

- Biofouling & Erosion Resistance

Product Description:

Monel mesh is a premium nickel-copper alloy (primarily Ni 63-70%, Cu 27-34%) wire mesh known for exceptional corrosion resistance, high strength, and durability in extreme environments. It outperforms stainless steel in many aggressive chemical and marine applications. Monel Mesh product has two types: monel wire mesh and monel perforated.

🔹 Monel Alloy Grades for Mesh:

| Grade | Composition | Key Properties | Best For |

| Monel 400 (UNS N04400) | 63-70% Ni, 27-34% Cu + Fe/Mn | Excellent corrosion resistance | marine & chemical industries |

| Monel K500 (UNS N05500) | Ni-Cu + Al/Ti (precipitation-hardened) | Excellent corrosion resistance, Higher strength | aerospace & deep-sea applications |

🔹 Key Properties & Advantages:

✔ Superior Corrosion Resistance

– Resists seawater, sulfuric/hydrochloric acid, alkalis, and hydrofluoric acid (better than stainless steel).

– Immune to chloride stress corrosion cracking (SCC).

✔ High Strength & Toughness

– Retains strength at cryogenic to 550°C temperatures.

– Monel K500 has twice the yield strength of Monel 400.

✔ Excellent Fabrication Properties

– Can be welded, brazed, and soldered easily.

✔ Biofouling & Erosion Resistance

– Ideal for marine filters, offshore platforms, and desalination plants.

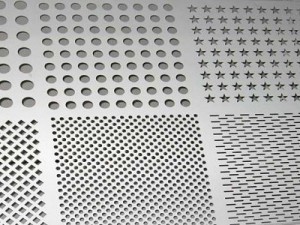

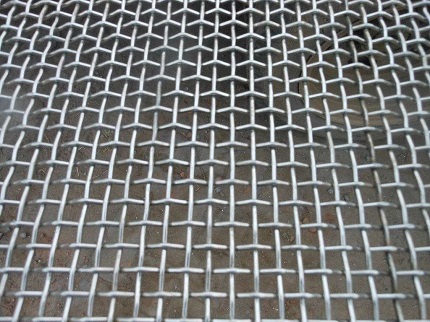

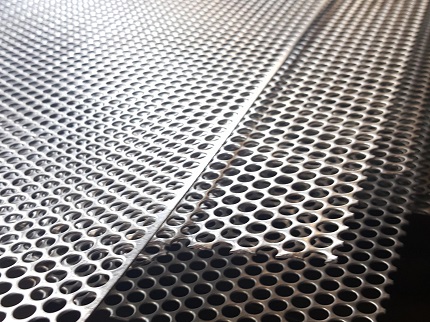

🔹 Weave Types & Specifications:

- Plain Weave (Most Common)

– Balanced, uniform openings for filtration, sieving, and shielding.

– Mesh Sizes: 2 to 200 mesh.

– Wire Diameters: 0.05mm to 3mm.

- Twilled Weave

– Stronger, denser weave for high-pressure filtration.

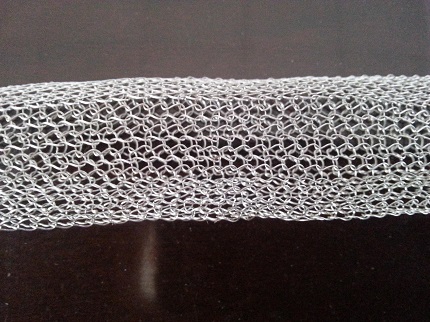

- Dutch Weave (Micron Filtration)

– Ultra-fine mesh for chemical processing and fuel filtration.

- Welded Mesh (Structural Use)

– Used in marine grates, architectural facades, and industrial screens.

🔹 Top Applications:

✅ Marine & Offshore

– Seawater intake screens, boat hulls, submarine components (resists biofouling).

– Desalination plants, offshore oil rigs.

✅ Chemical & Petrochemical

– HCl/HF acid filters, refinery components, reactor screens.

– Sulfuric acid production, chemical processing equipment.

✅ Aerospace & Defense

– Rocket components, jet engine parts (Monel K500).

✅ Power & Nuclear

– Cooling water systems, nuclear reactor components.

✅ Medical & Food Processing

– Antimicrobial filters, pharmaceutical sieves.

🔹 Monel vs. Other Alloys:

| Property | Monel 400 Mesh | 316L SS Mesh | Hastelloy C276 Mesh | Titanium Mesh |

| Seawater Resistance | ⭐⭐⭐⭐⭐ | ⭐⭐⭐ | ⭐⭐⭐⭐⭐ | ⭐⭐⭐⭐⭐ |

| Acid Resistance | ⭐⭐⭐⭐ (exc. in HF/H₂SO₄) | ⭐⭐ | ⭐⭐⭐⭐⭐ | ⭐⭐⭐ |

| Strength | ⭐⭐⭐ | ⭐⭐ | ⭐⭐⭐ | ⭐⭐⭐⭐ |

| Cost | $$$ | $ | $$$$$ | $$$$ |

✔ Better than 316L in: Hydrofluoric acid, seawater, high-strength applications.

✔ Cheaper than Hastelloy/Titanium but with similar performance in many cases.

🔹 Limitations:

❌ Expensive (higher cost than stainless steel).

❌ Heavier than titanium/aluminum.

❌ Not ideal for oxidizing acids (e.g., nitric acid).

Monel Mesh Product Pictures:

+1 206 890 7337

+1 206 890 7337 sales1@nickel-wiremesh.com

sales1@nickel-wiremesh.com