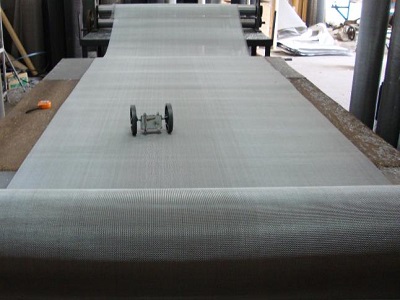

2205 Duplex Stainless Steel Mesh

Key Features:

- 2x stronger than 316L → Longer lifespan in harsh conditions.

- Better chloride & acid resistance → Ideal for seawater and chemical exposure.

- Higher fatigue resistance → Good for vibrating or high-stress environments.

- Cost-effective vs. super duplex (2507) → Stronger than 316L but cheaper than 2507.

Product Description:

2205 Duplex stainless steel mesh is a high-performance woven or welded wire mesh made from grade 2205 (UNS S32205/S31803), a ferritic-austenitic duplex stainless steel. It combines the best qualities of both austenitic and ferritic steels, offering superior strength, corrosion resistance, and durability compared to standard stainless steel meshes like 304 or 316.

Key Properties of 2205 Duplex Stainless Steel Mesh:

| Property | Details |

| Composition | ~22% Cr, 5-6% Ni, 3% Mo, 0.15-0.25% N |

| Density | 7.8 g/cm³ |

| Tensile Strength | 620-880 MPa (higher than 316L) |

| Yield Strength | 450-550 MPa (nearly 2x 316L) |

| Corrosion Resistance | Excellent in chloride, acidic, and high-temperature environments |

| Pitting Resistance Equivalent (PRE) | ≥35 (better than 316L) |

| Magnetic Response | Slightly magnetic (due to ferritic phase) |

| Temperature Range | -50°C to 300°C (higher than austenitic steels) |

Common Weave Types & Mesh Specifications:

2205 Duplex steel mesh is available in different weave patterns:

- Plain Weave (Most Common)

– Balanced, tight grid for filtration and structural use.

– Mesh Sizes: 1 to 200 mesh (openings from ~8mm down to 0.075mm).

– Wire Diameter: 0.05mm to 4mm.

- Twilled Weave

– Stronger, denser than plain weave, used in high-pressure filtration.

- Dutch Weave (Micron-Level Filtration)

– Fine mesh for filtering small particles in harsh environments.

- Welded Mesh (Structural Applications)

– Used in industrial grating, and chemical processing.

Applications of 2205 Duplex steel Mesh:

Due to its high strength and corrosion resistance, it’s used in demanding industries:

✅ Oil & Gas

– Offshore platforms, seawater desalination, pipe filters.

– Resists chloride stress corrosion cracking (SCC) better than 316L.

✅ Chemical & Petrochemical

– Acid filtration, reactor screens, heat exchangers.

✅ Marine & Desalination

– Saltwater filtration, shipbuilding components.

✅ Power & Energy

– Flue gas scrubbers, nuclear fuel processing.

✅ Food & Pharmaceutical

– Hygienic, corrosion-resistant filters for aggressive cleaning agents.

✅ Architectural & Security

– Decorative facades, blast-resistant panels (due to high strength).

Advantages Over Other Stainless Steel Meshes:

✔ 2x stronger than 316L → Longer lifespan in harsh conditions.

✔ Better chloride & acid resistance → Ideal for seawater and chemical exposure.

✔ Higher fatigue resistance → Good for vibrating or high-stress environments.

✔ Cost-effective vs. super duplex (2507) → Stronger than 316L but cheaper than 2507.

Limitations:

❌ Not suitable for extreme temps (>300°C) → Can lose duplex structure.

❌ More expensive than 304/316 → Justified for critical applications.

❌ Slightly magnetic → Not ideal for non-magnetic applications.

Alternative Materials:

– For higher temps/corrosion: Super Duplex 2507 Mesh (UNS S32750)

– For cost savings: 316L Mesh (if chloride exposure is moderate)

+1 206 890 7337

+1 206 890 7337 sales1@nickel-wiremesh.com

sales1@nickel-wiremesh.com